06

-

Overview

- Objectives for this week are:

- To understand the scope of the term ‘first fix’.

- To be able to interpret NRM2 🔗 Work section 16

- Apply work section 16 to practical examples.

- First and second fix

- First fix usually refers to structural work, which is done before the plastering and finishes are carried out. This includes, for example; stud partitions, floor joists, etc. The second fix is the finishing work, usually done after the plastering for example; skirtings, architraves and linings and is carried out with planed or finished timber.

- Electricians can lay cables and plumbers can fix pipes in the roof, walls and floor when the first fix is complete, prior to the finishes being applied.

- First fix work is generally in sawn or carcassing timber.

- Note; a 50 x 25mm timber section may be specified in two ways in a specification or bill of quantities;

- 50 x 25mm un-planed (ex, or sawn) or

- 46 x 21mm planed, finished or wrot or nominal

- Nominal sizes are approximately 4mm less than ex.

- Section 16 of NRM2 states all work in 🔗 Carpentry is deemed to be sawn, although there are items measureable in section 16 that are generally carried out in wrot or finished timber, fascias for example, (16.4).

- In addition to timber metal fixings are also measured under Work section 16.

- Note that roofing is dealt with separately in Week 7.

- Activities

- 1. Familiarise yourself with the items that are deemed to be included when measuring carpentry works.

- 2. Identify items within the carpentry section that are generally formed from wrot timber.

- 3. Convert 75 x 50mm sawn timber to its’ nominal size.

- 4. List some examples of second fix work.

-

NRM2 Section 16; Carpentry

- Objectives

- To understand the principles to be taken into account when measuring carpentry timbers

- To interpret work section 16 of NRM2 to measure a timber upper floor

- Generally

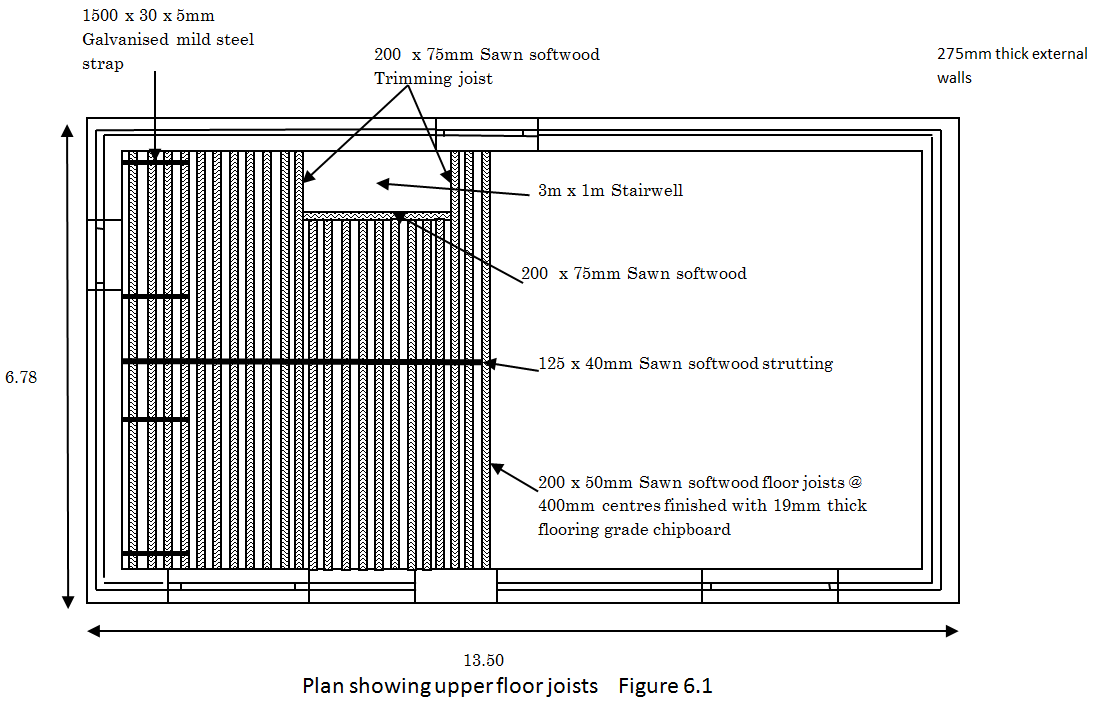

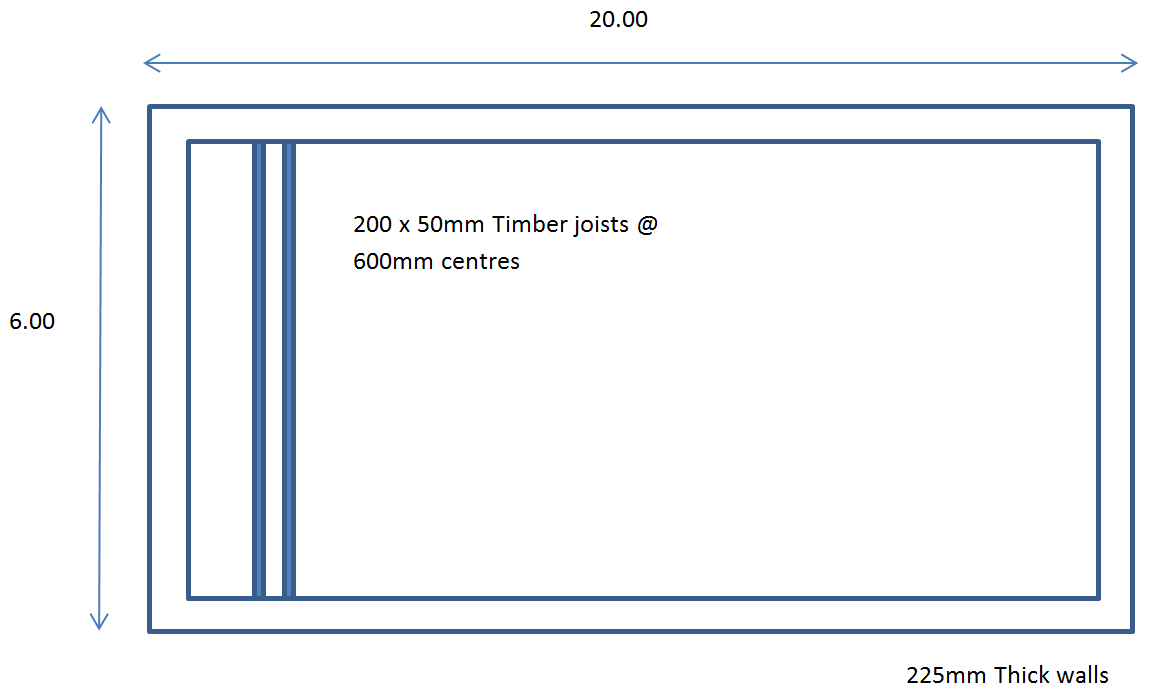

- Have a look at the plan of a typical timber upper floor in figure 6.1

- The following considerations apply, not only to upper floors, but also, any situations where carpentry timbers are used;

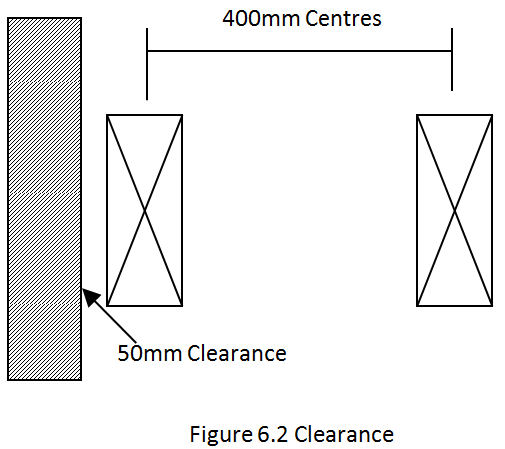

- The clearance between the first and last joist and the external wall see figure 6.2

- The layout of the floor joists (200 x 50mm)

- The thicker joists (200 x 75mm) needed to form or trim the opening for the stairwell or other openings

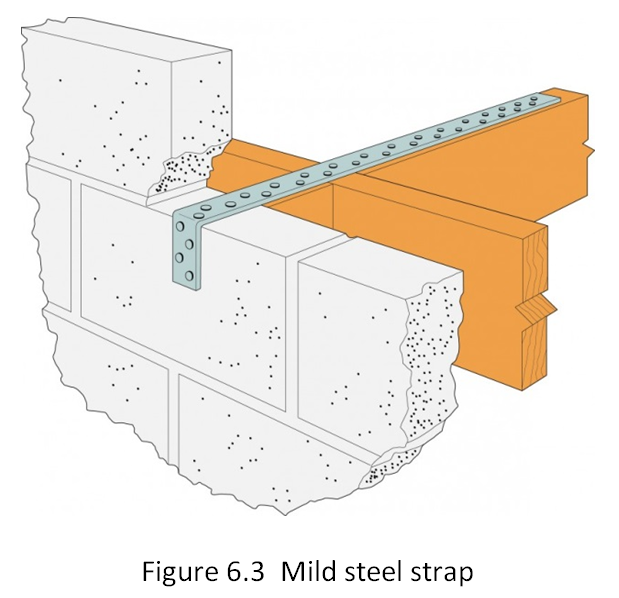

- The galvanised 🔗 mild steel straps – see figure 6.3

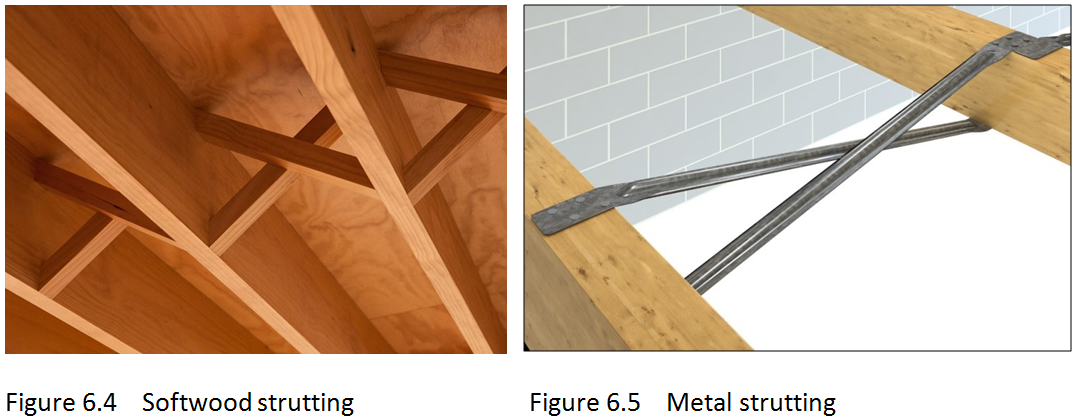

- The softwood and metal strutting – see figure 6.4 and figure 6.5

- Joist hangers

- Although not necessary in this case; timber over 6m long, required in one piece, has to be described and measured separately.

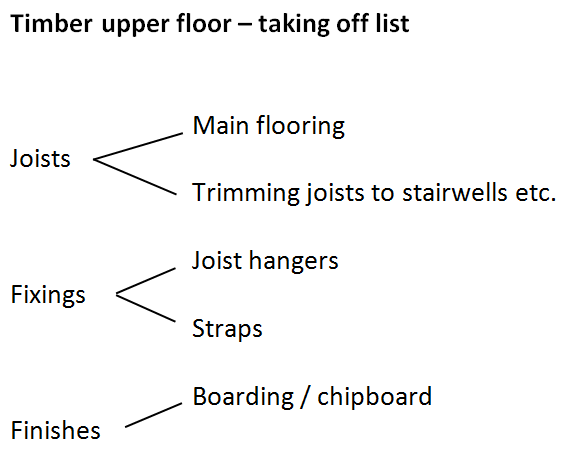

- Before moving onto the 🔗 measurement of the timber floor, ❚❚ have a look at the taking off list below

- (N.B. When you click on the link above a pdf file will open along with an audio track, to pause the audio you must click on the pause icon)

- Activities

- 1. Referring to figure 6.1 identify the nature and type of metal fixings required.

- 2. Calculate the length of the strutting required.

- 3. Sketch a section through a typical suspended timber upper floor showing; the joists, the strutting, the flooring and any fixings.

- 4. When measuring carcassing timber in accordance with NRM2 are the bolt and the hole through the timber for the bolt shown below, deemed to be included or are they measureable?

-

NRM2 Section 16; Carpentry: Stud Partition

- Objectives

- To understand the construction of timber stud partitions

- To apply work section 16 of NRM2 to measure stud partitions

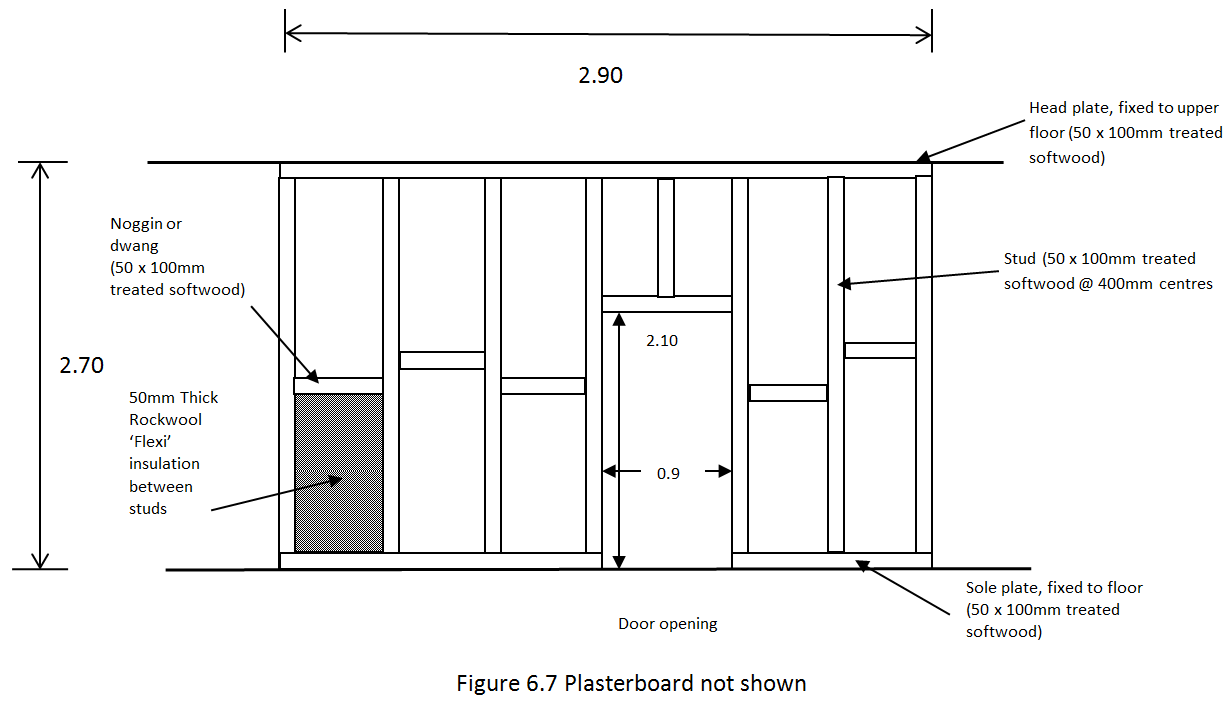

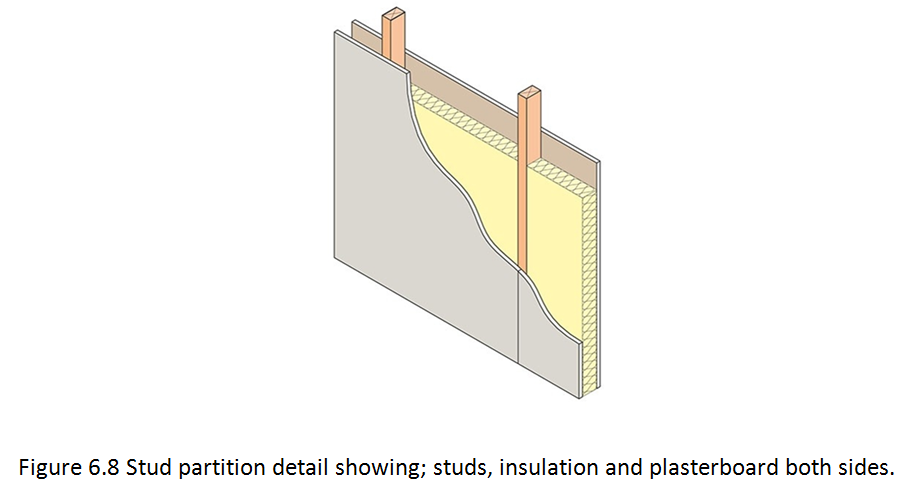

- Figures 6.7 and 6.8 show details of a typical timber stud partition

- Timber stud partition

- The principle is similar to measuring a timber floor;

- Calculate the number and length of 🔗 partition members

- Include to the head and sole plate, which may have to be fixed by plugging to concrete or other materials

- The noggins or dwangs are included in this example as part of the partition members, however, I can see a case for measuring them as strutting.

- The insulation is measured in accordance with NRM 2 🔗 Work section 31

- Activities

- 1. Look at the floor plan below. Calculate the number and length of the floor joists required

-

Engineered and pre-fabricated members

- Objectives

- To identify and understand how to measure and describe prefabricated carpentry items

- Generally

- NRM2 Section 16.2 deals with the measurement of prefabricated items

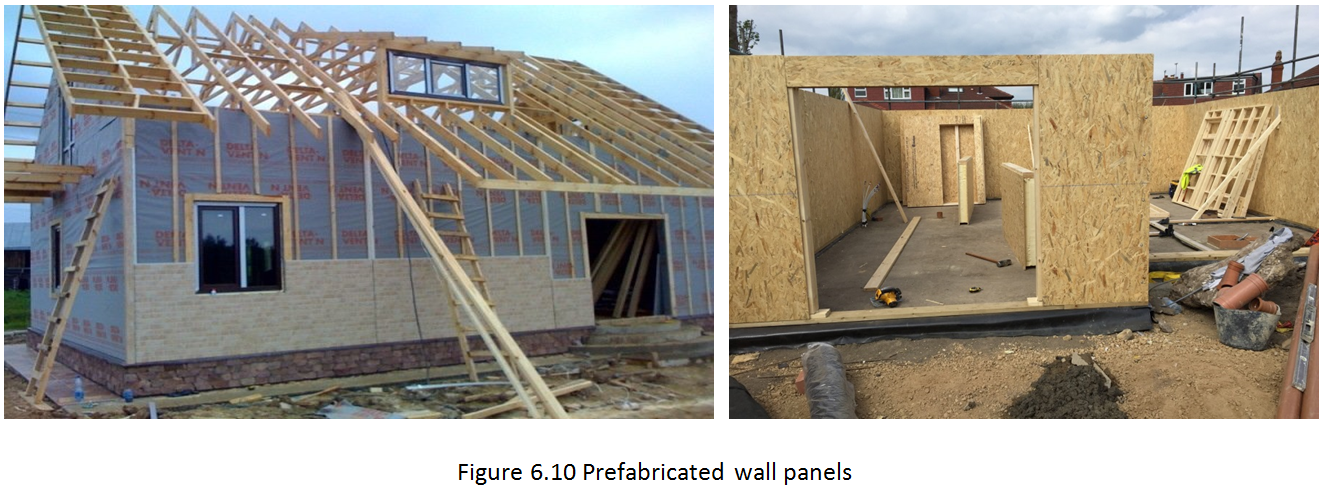

- During the last 30 years or so more building components have been fabricated off-site, in factory controlled conditions and brought to site.

- This approach has many advantages, e.g. health and safety.

- Construction has, like car manufacturing, moved from a building to an assembly process.

- In carpentry examples of this approach are found in;

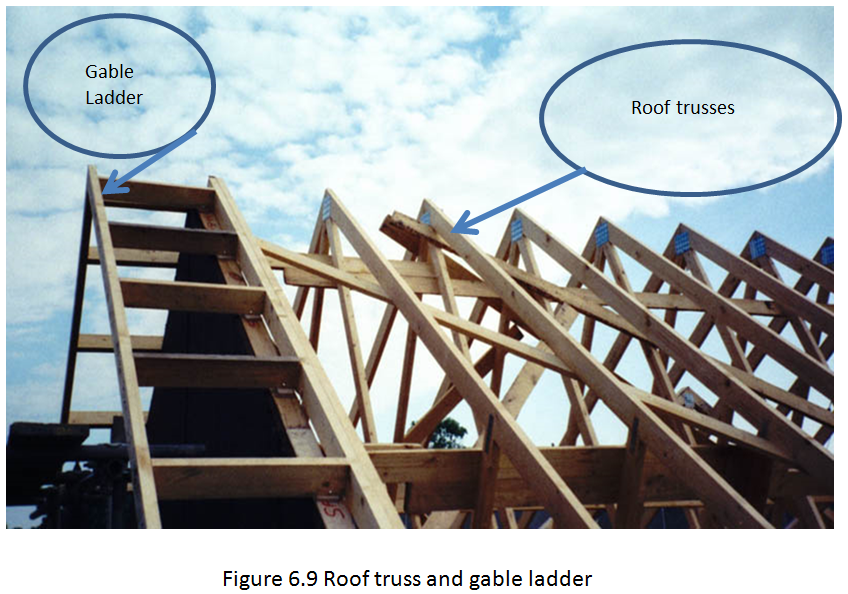

- Roof trusses

- Gable ladders

- External walls

- Typical roof truss description;

- Hoisting prefabricated items into position is deemed to be included.

- Prefabricated units make wide use of 🔗 metal timber connectors

- NRM2 Work section 2 – 🔗 Off-site manufactured materials, components and buildings may also be used to measure prefabricated components if Carpentry is inappropriate.

- Activities

- 1. When measuring joist hangers what information should be given in the description?

- 2. When is board flooring measured in linear meters?

- 3. Battens are required to be specified by their nominal dimension – what is this?

- 4. Why are carpentry timbers over 6m long, in one length, required to be so described?

-

Learning Outcomes

- On completion of this week you should be able to;

- 1. Identify which timber items are measured using NRM2 Work section 16.

2. Calculate the number of structural timbers required in a timber floor or stud partition.

3. Compose a description for simple carpentry items.

4. Recognise engineered or prefabricated items.

5. Understand which items are deemed to be included with carpentry items.

6. Appreciate the importance of metal fixings and fastenings in carpentry work.

7. Identify the minimum information that should be available prior to measuring carpentry work.

- Insert Content Here

- Insert Content Here