Wk 10 - A & B

Applications

- High velocity ratios with moderate size gears in a comparatively lesser space

- For example:

– Back gears of lathes– Differential gears of automobiles– Hoists– Pulley blocks– Wrist watches– Etc.

Epicyclic Gears

- Introduction

– Applications- Velocity Ratio

- Compound Gear Trains

- Solved Problems

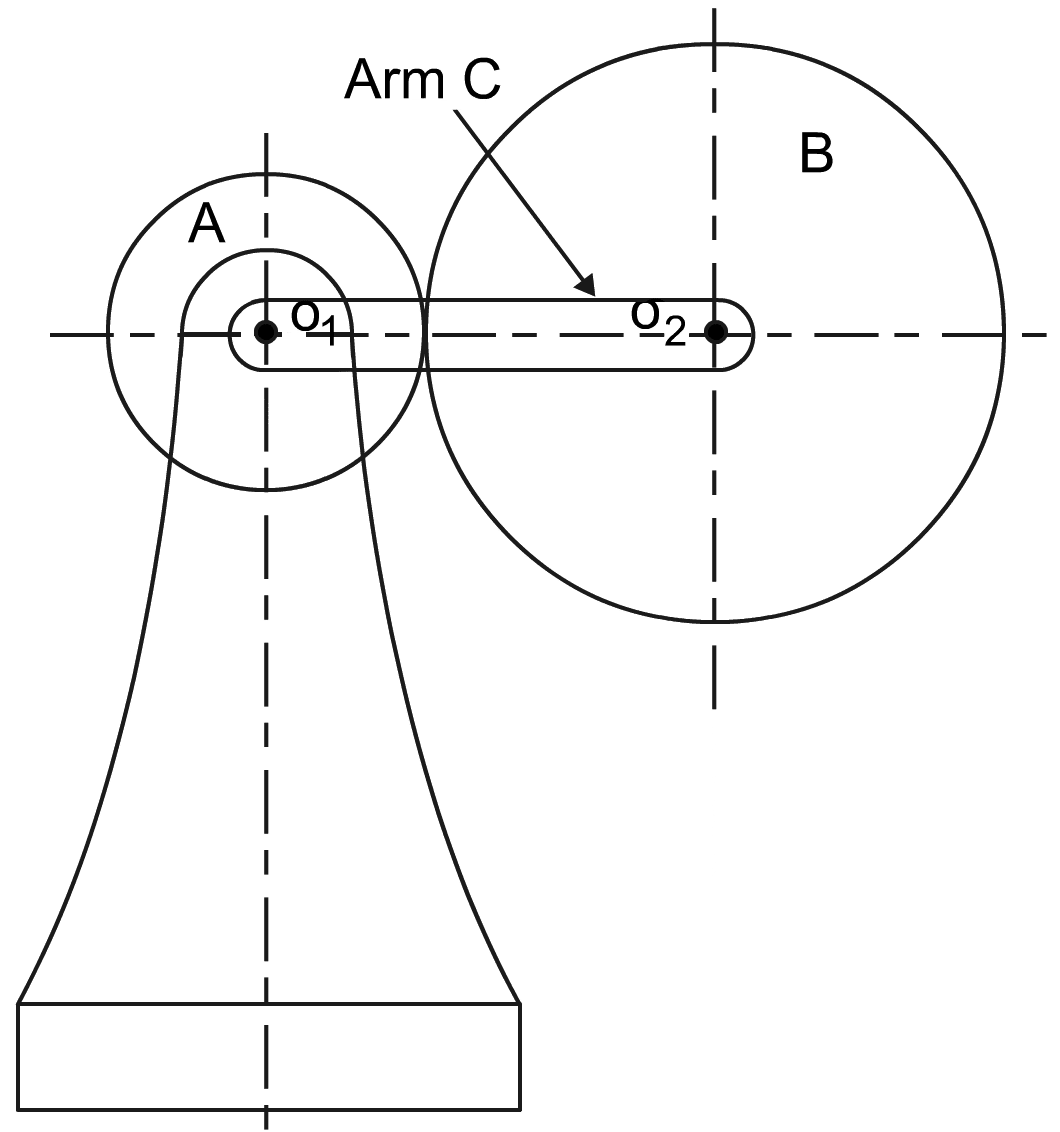

Introduction

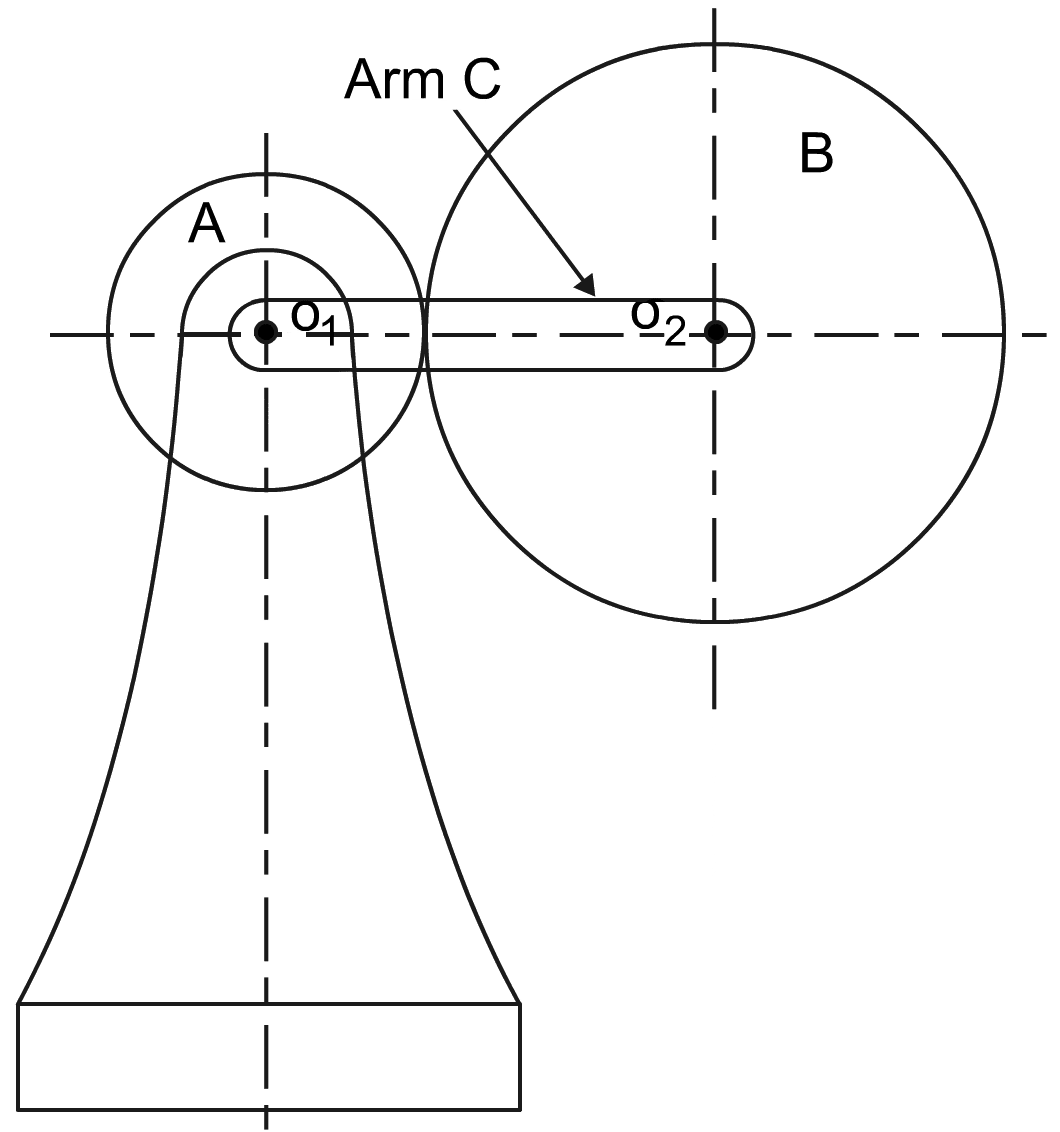

- Arm C Fixed

– Gear A or Gear B is driver of other gear- Gear A Fixed

– Gear B rotates upon (epi) and around (cyclic) Gear A

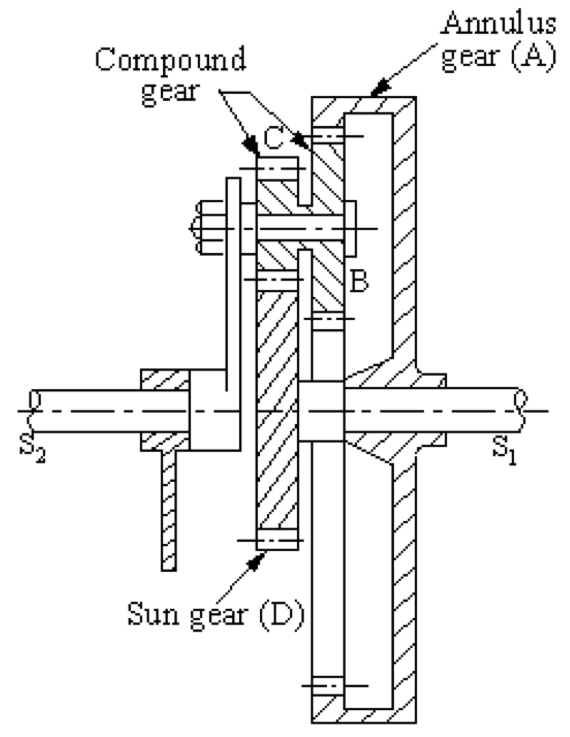

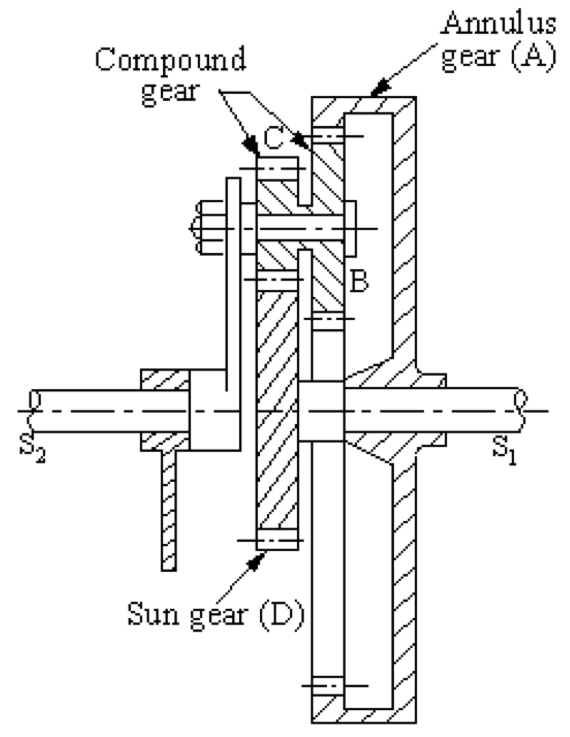

Compound Gear Train

- 📷 Compound Gear Train cross section - enlarge above image

- Co-axial shafts S1 and S2

- Annulus Gear A

– Internal Teeth- Compound Gear (Planet) B-C

– Carried by Arm and revolves freely on pin- Sun Gear D

– Co-axial with A and H but independent- Arm H

– When A is fixed, D provides the drive– When D is fixed, A provides the drive– H acts as a follower for both cases

Continues on next tab.

Velocity Ratio

- zA = number of teeth on Gear A

- zB = number of teeth on Gear B

- Assume Arm C, in the diagram above, is fixed

– Therefore axes of arms fixed relative to each other- Assume Arm C is fixed

– Therefore axes of arms fixed relative to each other, and:$$ \large \frac{N_B}{N_A} \; = \; \frac{z_A}{z_B} \quad Eqn.(5.1)$$– When A makes one revolution anticlockwise, B makes zA/zB revolutions clockwise- Assume anticlockwise is positive rotation and clockwise is negative rotation

- For Gear A making +1 revolutions, Gear B makes: $ \bigg( - \Large \frac{z_A}{z_B} \bigg) $ revolutions.

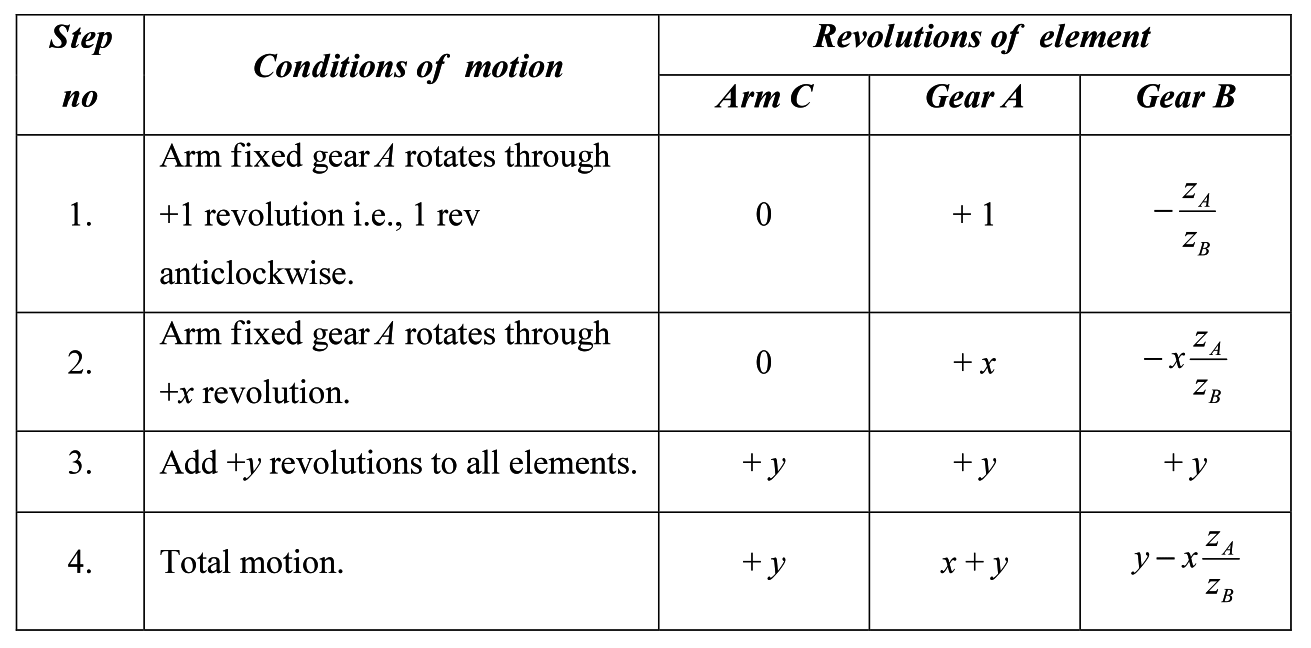

- 📷 Velocity Ratio Table

- The equations above can be used to generate the magnitude of the revolution value, but the directions must be taken from the following rules:

– Gears that mesh external teeth to external teeth rotate in opposite directions.– Gears that mesh external teeth to internal teeth rotate in the same direction.

- Velocity Ratio Table - Run Through Video

- Worked example 1 - Epicyclic Gears Video

- ⬇ Download worked example

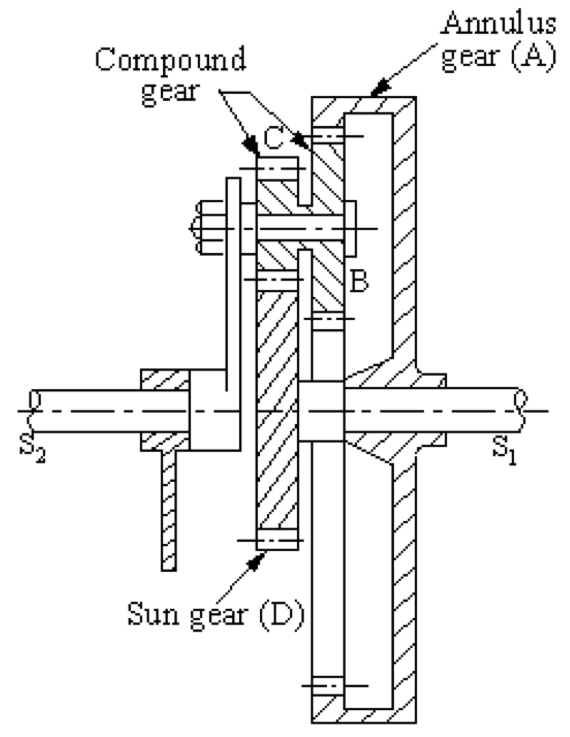

Compound Gear Train (cont.)

- 📷 Compound Gear Train cross section - enlarge above image

- zA, zB, zC and zD number of teeth for each gear

- NA, NB, NC and ND speed of each gear

- When H is fixed, D is turned anti-clockwise, B-C and A rotate in clockwise direction

- From Equation (5.1) for ND = 1: $$ \large N_c = \frac{z_D}{z_C} \quad Eqn.(5.2) $$

- As B-C is a compound gear, NB = NC, and the next speed ratio to consider is NA/NB. Therefore; $$ \large \frac{N_A}{N_B} \; = \; \frac{z_B}{z_A} \quad Eqn.(5.3) $$

- Re-arranging for NA:

$$ \large N_A = N_B \times \frac{z_B}{z_A} \; \quad Eqn.(5.4) $$- Substituting the value for NB from Equation (5.2) (equal to NC):

$$ \large N_A = \frac{z_D}{z_C} \times \frac{z_B}{z_A} \quad Eqn.(5.5) $$

- The equations above can be used to generate the magnitude of the revolution value, but the directions must be taken from the following rules:

- Slope of thread($ \theta $)

- It is the inclination of the thread with the horizontal

Mathematically,- $$ \text{tan} \; \theta = \frac{Lead of screw}{Circumference of screw} = \frac{l}{ \pi D _{ms}} $$

$ l $ =lead of the screw = $ np $

$ p $ = pitch of the screw

$ D _{ms} $ = Mean diameter of the screw, and

$ n $ = number of start threads

- Derivation of the Angle of a Thread Equation Video

Design of Power Screws

- Introduction

- Nomenclature- Screw Jacks

- Torque Required- Efficiency- Overhauling and self-locking screws

Introduction

- Screws

- Made by cutting continuous helical groove on a cylindrical surface- External ThreadsCut on outer surface of a solid rod- Internal ThreadsCut on the inner surface of a hollow rod- V-ThreadsStronger and higher friction resistance than square threadsPrevent nut from slackeningUsed for bolts and nuts- Square ThreadsUsed for screw jacks, vice screws, etc.Nomenclature

- Helix

- Curve traced by particle moving along screw thread- Pitch

- Distance between screw threads- Lead

- Distance screw thread advances axially in one turn- Depth of Thread

- Distance between top and bottom surfaces of thread- Single-Threaded Screw

- Lead of the screw is equal to the pitch- Multi-Threaded Screw

- More than one thread is cut in one lead distance of a screw, e.g. double threaded screw has two threads cut in one length

Lead = Pitch $ \times $ Number of Threads- Slope of thread($ \theta $)

- (Cont.)

- Or with no collar bearing: $$ T = W \; tan \; ( \phi + \theta ) \frac{D _{ms}}{2} \quad \small \textbf{Eqn(6.3)} $$

- And to calculate the force P at the end of a lever length L to apply this torque: $$ T = W \; tan \; ( \phi + \theta ) \frac{D _{ms}}{2} + W \mu _c \frac{D _{mc}}{2} = P \times L $$

Screw Diameters

- Nominal Screw Diameter (DO)

- Also known as outside diameter or major diameter- Core Diameter (DC)

- Also known as outside diameter or major diameter- Mean Diameter (DM)

$$ D _{m} = \frac{D_o + D_c}{2} = D _o - \frac{p}{2} = D _c + \frac{p}{2} $$

- If the nominal and/or the core diameter are known:- Working Out the Mean Diameter of the Screw Video

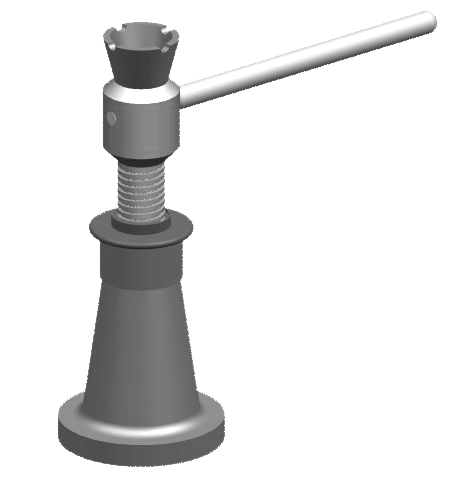

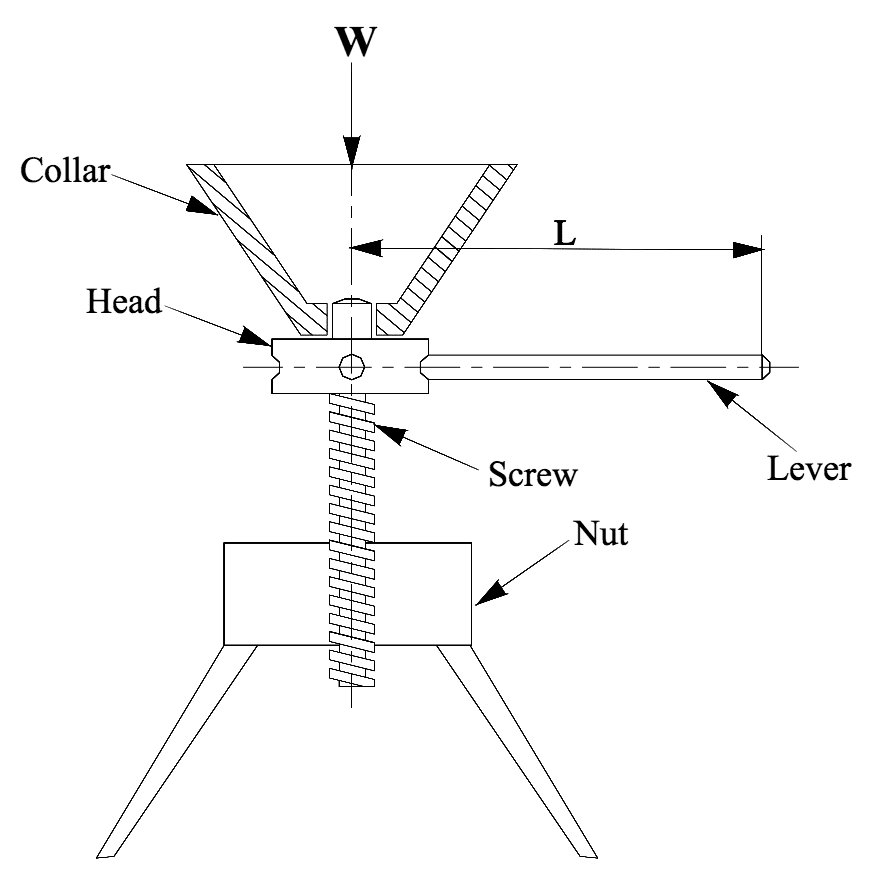

Screw Jack

Screw jack with thrust collar

Screw jack with thrust collar

- Used to lift heavy loads by applying comparatively small effort at the handle

- Works on principle similar to inclined plane

- Load to be raised or lowered is placed on head of square threaded rod

- Square threaded rod rotated by application of force at end of the lever

Required Torque

- Torque required to lift the weight

Where:

$ p $ = pitch of the screw

$ D _{ms} $ = Mean diameter of the screw

$ D _{mc} $= Mean diameter of the collar

$ \theta $ = helix angle

$ W $ = load to be lifted

$ \mu _{s}$ = coefficient of friction of screw thread, i.e., between the screw and nut = tan $ \phi $ , where $ \phi $ is the friction angle

$ \mu _{c}$ = coefficient of friction of collar bearing

- Therefore

- A screw will always be self locking if:the friction angle is greater than the helix angle, orthe coefficient of friction is greater than the tangent of the helix angle

- Comparison of Thread Angle and Angle of Friction Video

- Worked Example 2 Introduction Video

- ⬇ Power Screws Nomenclature

- ⬇ Power Screws Worked Examples

Efficiency of a Screw Jack

- Efficiency defined as:

- Ratio between the ideal effort (neglecting friction) to the actual effort (taking friction into account- Remember:

$$ T = W \; tan \; ( \phi + \theta ) \frac{D _{ms}}{2} + W \mu _c \frac{D _{mc}}{2} \quad \small \textbf{Eqn(6.6)} $$

- For no friction, $ \mu _s $ = 0, therefore:

$$ T _0 = W \; \text{tan} \; \theta \frac{D _{ms}}{2} $$- Therefore, efficiency equation defined as: $$ \mu = \frac{T_0}{T} = \frac{W \; \text{tan} \; \theta \; \frac{\large D _{ms}}{2}}{W \; tan \; ( \phi + \theta ) \frac{\large D _{ms}}{2} + W \mu _c \frac{\large D _{mc}}{2}} $$

or for no collar bearing: $$ \eta = \frac{tan \; \theta}{tan \; (\theta + \phi)} $$

Overhauling and Self-Locking Screws

- Torque required to lower the load: $$ T = W \; tan \; ( \phi - \theta ) \frac{\large D _{ms}}{2} + W \mu _c \frac{\large D _{mc}}{2} $$

- If $ \phi $ < $ \theta $

- Torque required to lower the load may be negativeLoad moves down without application of torqueKnown as overhauling- If $ \phi $ > $ \theta $

- Torque required to lower the load will always be positiveEffort is required to lower the loadKnown as self-locking- Therefore